This guide is for prospective tiny house builders, designers, and DIY enthusiasts. Designing a tiny house requires meticulous attention to every inch of space, and tiny house wall thickness plays a pivotal role in maximizing usable interior area while maintaining structural integrity. The thickness of the walls can take up 9-17% of the overall width of a tiny house, which directly impacts the amount of usable space inside. This guide explains how tiny house wall thickness affects design, insulation, and usable space. Tiny houses, especially those on wheels, typically have limited floor space—often no more than 320 square feet—so even small variations in wall thickness can significantly impact the interior room available. Builders must balance the need for strong, insulated walls with the desire to keep the home lightweight and mobile.

- Exterior walls: 4.5–6 inches

- Internal walls: 4.5 inches

- Non-load bearing interior walls: 2.5 inches

Wall thickness matters for energy efficiency, comfort, and space optimization: thicker, well-insulated walls help maintain a comfortable indoor temperature, reduce energy costs, and maximize the livable area within the tiny house.

Understanding local building codes and regulations is also essential. These codes dictate minimum requirements for structural strength, insulation, fire safety, and more, all of which influence wall construction choices. Building codes (code) often specify minimum wall thickness and material requirements to ensure safety and compliance. Whether you are building a tiny house for personal use or to meet specific regional standards, knowing these rules upfront helps ensure your project is both safe and compliant.

Framing a tiny house is an important step because it provides the structural support for the home.

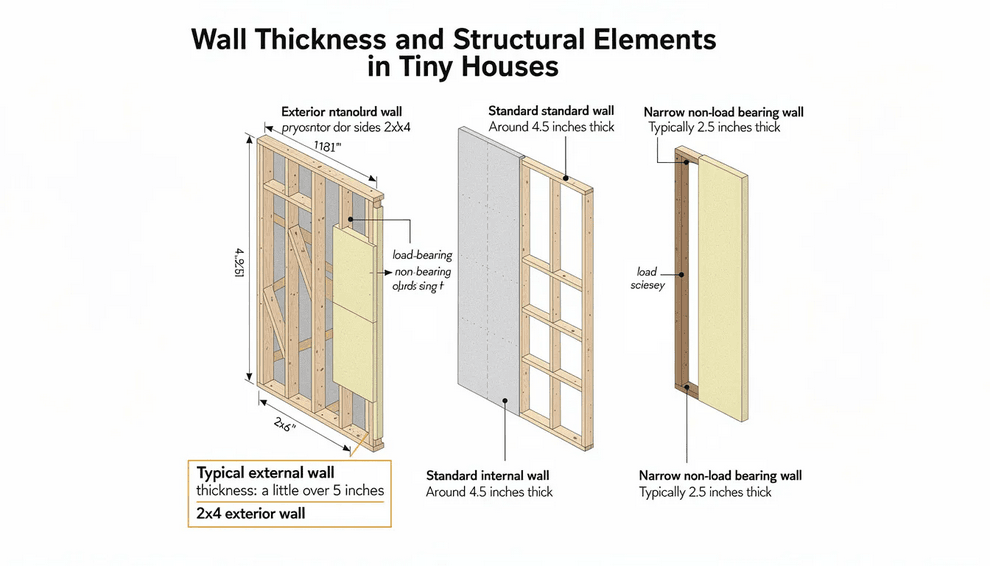

Wall Thickness and Structural Elements

Typical Wall Thickness

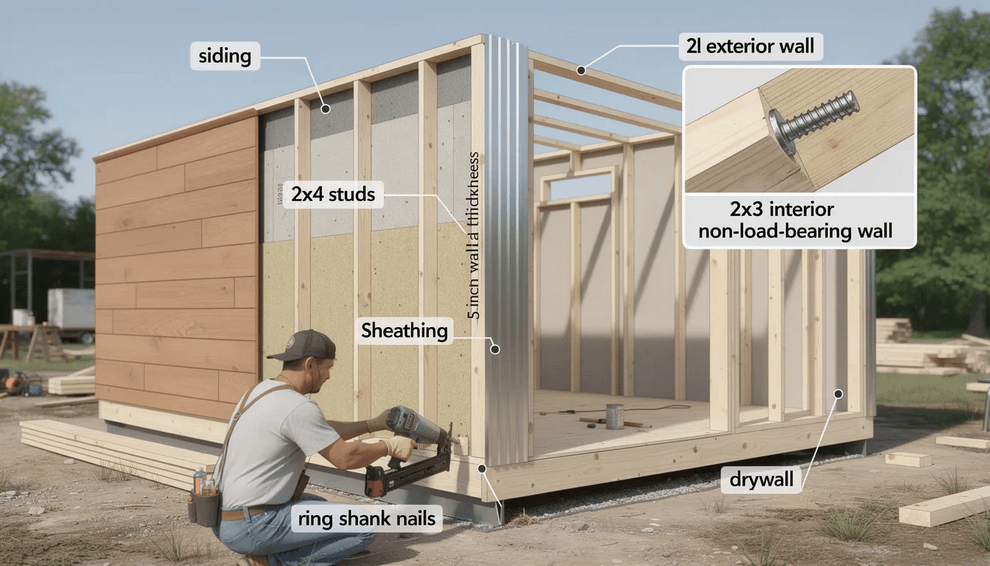

Recommended wall thickness for tiny houses typically ranges between 4.5 and 6 inches. The typical external wall thickness of a tiny house using standard 2×4 wood is a little over 5 inches. The thickness of a standard internal wall in a tiny house is around 4.5 inches due to the drywall on both sides. Narrow walls, which are typically 2.5 inches thick, are often used for non-load bearing interior walls in tiny houses.

Interior vs. Exterior Walls

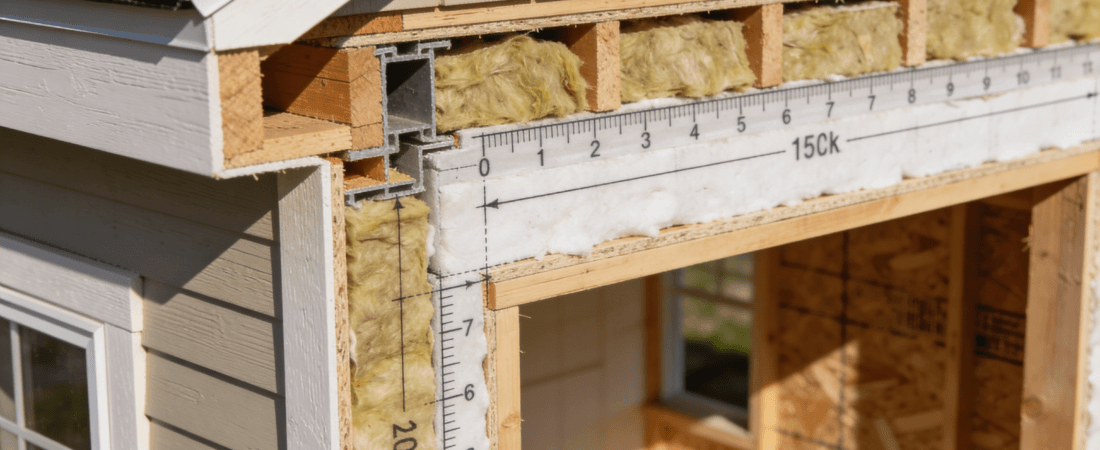

The typical wall thickness in a tiny house ranges between 4 to 5 inches. This measurement includes several layers: the exterior siding, sheathing, the wood framing (usually 2×4 studs), insulation, and the interior drywall or paneling, which is typically hung or installed on one side of the wall framing. Exterior walls are generally constructed with 2×4 wood framing, providing a sturdy skeleton that supports the roof and withstands environmental stresses.

Interior walls, on the other hand, are often non-load bearing and can be thinner, sometimes using 2×3 or even 2×2 studs depending on local building codes and intended use. Narrow walls, which are typically 2.5 inches thick, are often used for non-load bearing interior walls in tiny houses to save space. These walls help define spaces inside the tiny house, such as bedrooms, bathrooms, or storage closets, without adding unnecessary weight or bulk.

Fasteners and Framing Details

To assemble the framing securely, builders commonly use ring shank nails or screws. Using ring shank nails is recommended for framing walls in tiny houses to ensure a strong hold. Ring shank nails offer excellent holding power, resisting pull-out forces better than smooth nails, which is critical for the longevity and safety of the structure. When attaching wall sheathing, using glue and screws can provide additional strength, but nails are generally preferred for shear strength. Using screws for wall sheathing can be less effective than nails due to lower shear strength, but they can still be used if chosen carefully. The top plate and bottom plate—horizontal framing members at the top and bottom of the wall studs—are crucial for transferring loads and ensuring the walls remain straight and stable. Careful marking and cutting of these plates during construction are vital steps for a well-built wall.

When it comes to interior finishes, drywall or paneling is typically hung or installed on one side of the wall framing. The process to install drywall or partitions is straightforward and helps create a clean, finished look inside the tiny house.

Exterior Wall Components and Materials

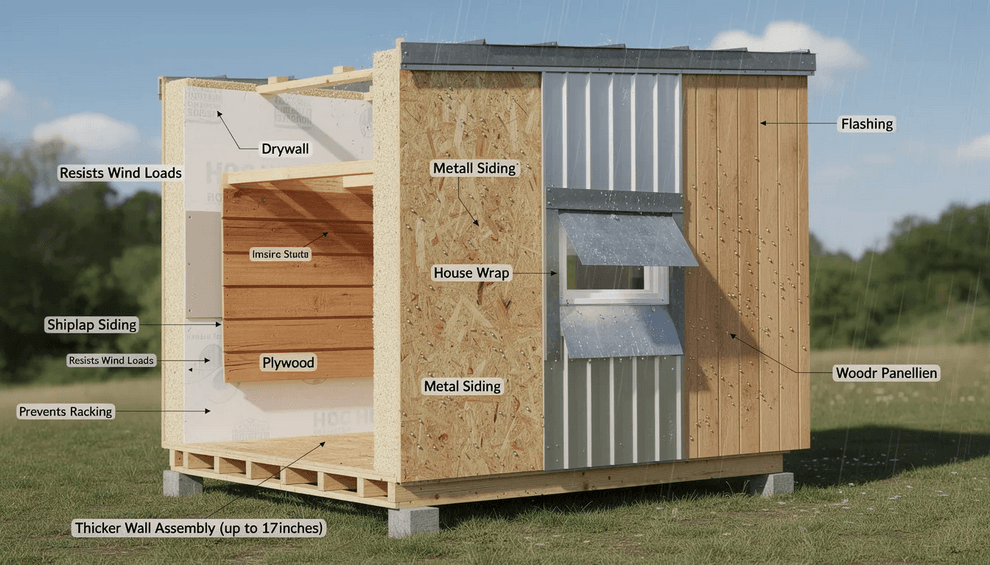

The exterior wall assembly significantly influences the wall thickness and the tiny house’s overall aesthetic. Walls are typically covered with layers such as sheathing, insulation, and siding to improve thermal performance and structural integrity. Popular siding options include shiplap, metal siding, and wood paneling. Shiplap siding is favored for its rustic charm and durability, and it is more resilient against minor roof leaks and humidity issues compared to drywall, but it tends to be thicker and more costly than alternatives like metal siding, which offers a thinner profile and modern look.

Beneath the siding, plywood or oriented strand board (OSB) sheathing provides structural rigidity and a solid base for attaching the siding. Drywall is a cost-effective sheathing material for tiny houses. This sheathing layer also helps resist wind loads and prevents racking (sideways movement) of the walls.

When considering wall thickness, the overall wall thickness can increase significantly if thicker insulation or additional materials are used, potentially reaching up to 17 inches in some cases. Thinner wall assemblies may be fine in milder climates, but thicker assemblies are preferred in harsher conditions.

Because tiny houses must endure various weather conditions—from heavy rain and wind to cold winters—exterior walls are designed to be weather-resistant. Incorporating house wrap and vapor barriers is essential to prevent moisture intrusion and condensation within the wall cavity. Proper flashing around windows and doors is also crucial to prevent water intrusion. House wrap acts as a breathable membrane that blocks water while allowing vapor to escape, reducing the risk of mold and rot. Vapor barriers, typically installed on the interior side, help control moisture movement and protect insulation performance. Proper wall assembly can minimize worry about condensation and moisture issues.

Building Tiny House Walls

Framing Materials

Constructing walls for a tiny house is a process that demands both precision and creativity, as every inch of wall thickness can influence the comfort, efficiency, and overall feel of your home. In a typical tiny house, exterior walls are usually about 5 inches thick, a measurement that includes the exterior siding, sheathing, framing, insulation, and interior finishes like drywall. The choice of exterior siding—whether ship lap for a classic look or metal siding for a modern, low-maintenance finish—can affect this thickness, as well as the overall weight and durability of the house.

When it comes to framing, using quality materials and proven construction techniques is essential. Most builders opt for wood studs, with 2x4s being standard for exterior walls to provide enough space for insulation and structural support. Ring shank nails are a popular fastener, as their design offers superior holding power, which is especially important for tiny homes that may be moved or exposed to harsh weather. For non load bearing walls, such as those dividing the interior into rooms or closets, thinner studs like 2x3s can be used to save valuable space and reduce material costs.

Insulation Choices

Insulation is a key consideration, particularly in colder climates where thicker walls allow for more insulation and a cozier interior. Spray foam is a favorite among tiny house builders because it maximizes insulation in tight spaces and helps prevent drafts. To further protect against condensation and moisture, vapor barriers and house wrap are installed as part of the wall assembly, while an air gap can improve ventilation and prevent mold growth.

Interior Finishes

The design of your tiny house floor plan should take wall thickness into account from the start. Thicker walls mean slightly less interior space, so careful planning is needed to ensure that every square foot is used efficiently. Features like built-in cabinets, shelves, and even sliding glass doors can help create a sense of openness and provide much-needed storage without sacrificing comfort. Large windows not only bring in natural light but also make the space feel larger and more inviting.

Roof framing and roof overhangs are also important elements. A well-designed roof overhang will shield your exterior walls and windows from rain and snow, extending the life of your siding and reducing maintenance. The integration of the roof with the wall framing must be precise to ensure structural integrity and weather resistance.

Material selection plays a big role in both the cost and performance of your tiny house walls. Plywood is a cost-effective choice for sheathing, providing strength and a solid base for siding. Drywall is commonly used for interior walls, offering a smooth, paintable surface. For those looking to save money or add character, reclaimed wood or recycled materials can be used for both exterior siding and interior finishes, provided they meet local building codes and are installed properly.

Throughout the construction process, it’s crucial to follow local building codes and best practices to ensure your tiny house is safe, durable, and up to standard. Attention to detail—such as properly sealing around windows and doors, using the right fasteners, and ensuring adequate insulation—will pay off in the long run with a more comfortable and energy-efficient home.

Ultimately, building tiny house walls is about finding the right balance between wall thickness, insulation, cost, and design. With thoughtful planning, quality materials, and a focus on both function and aesthetics, you can create walls that not only protect and insulate your tiny home but also contribute to a beautiful and inviting living space. Whether you’re a seasoned builder or tackling your first tiny house project, investing time and care into your wall construction will help ensure your home stands the test of time.

Building and Design Considerations for Tiny Houses

There are a few reasons why wall thickness is a key consideration in tiny house construction:

- Structural stability

- Insulation

- Energy efficiency

- Maximizing interior space

Deep, well-insulated walls are easier to make airtight, preventing significant energy loss in small structures. Thicker wall systems can also incorporate a thermal break to stop heat transfer through studs, further improving thermal performance. However, 2×6 walls can reduce interior width by up to 4 inches, impacting usable space in tiny homes. Recommended wall thickness for tiny houses typically ranges between 4.5 and 6 inches.

A well-thought-out floor plan can help minimize wall thickness without compromising strength. For example, placing plumbing and electrical lines along one wall or consolidating them in cabinetry can reduce the need for wider walls. Similarly, choosing thin interior wall materials to maximize interior space, or using advanced framing techniques—such as spacing studs at 24 inches on center instead of the traditional 16 inches—can save space and materials. The thickness of a standard internal wall in a tiny house is around 4.5 inches due to the drywall on both sides. Floor planning software often includes options to represent wall thickness accurately, giving builders a better idea of space usage. Having a rough idea of wall construction helps visualize how these choices affect the final layout. Thinking through different construction methods can help optimize both space and insulation.

Roof framing and roof overhangs also affect wall thickness and the overall design. Proper roof overhangs protect walls from rain and sun exposure, extending their lifespan and improving energy efficiency by shading windows and walls. The rest of the roof framing, such as birds mouth notches, must sit properly on the wall’s top plate for stability. Roof framing must be integrated with wall framing to ensure structural stability, often adding to the overall wall height and thickness at the top plate.

Material cost and weight are critical considerations for tiny house builders. Lightweight materials reduce the load on the trailer and improve fuel efficiency during transport. However, budget constraints may limit material choices, requiring compromises between cost, durability, and performance.

Insulation and Weather Resistance

Insulation Requirements

In colder climates, thicker walls with better insulation can help maintain a comfortable indoor temperature. Effective insulation is critical in tiny houses to maintain a comfortable interior temperature year-round and reduce energy consumption.

| Climate Zone | Recommended R-Value | Typical Wall Thickness |

|---|---|---|

| Temperate | R-13 to R-15 | 4.5–5 inches (2×4 framing) |

| Colder | R-19 to R-21 | 5.5–6 inches (2×6 framing) |

| High-Performance | R-20 to R-30+ | 6+ inches (with spray foam) |

When insulating, aim for R-13 to R-15 in temperate zones and R-19 to R-21 for colder regions. Upgrading to a 6-inch wall can significantly reduce long-term utility costs in colder regions. In colder regions, 2×6 framing prevents heat loss and avoids condensation issues, and 2×6 framing (5.5 inches) is recommended for wall thickness in colder climates for higher R-value insulation. Using 2×6 wood for framing allows for thicker insulation, typically offering R-20 or R-21 protection.

Framing for Insulation

Spray foam insulation is a popular choice because it provides excellent thermal performance, seals air leaks, and adds structural rigidity. 2×6 framing can achieve R-20 to R-30+ insulation with high-performance materials like closed-cell spray foam. High-density, closed-cell spray foam insulation can provide over R-25 in a 2×6 wall. However, it is generally more expensive than fiberglass or mineral wool batts.

Including air gaps and ventilation within wall assemblies helps prevent condensation, which can lead to mold growth and material deterioration. Ventilation systems such as energy recovery ventilators (ERVs) or heat recovery ventilators (HRVs) promote healthy indoor air quality by exchanging stale indoor air with fresh outdoor air while conserving energy. When insulating and finishing, don’t forget to insulate the ceiling to prevent heat loss and improve overall energy efficiency.

Weatherproofing Details

Exterior siding and sheathing materials must be durable and water-resistant to withstand weathering. Proper flashing around windows, doors, and corners is essential to channel water away from the walls. Additionally, roof overhangs and drip edges help protect walls from direct water exposure.

If you are converting a shed into a tiny home, special attention should be given to insulation and wall thickness to ensure comfort and energy efficiency. For a tiny house on wheels, careful consideration of wall thickness and insulation is necessary to balance mobility, structural integrity, and comfort.

Final Considerations for Builders

Building a tiny house demands careful planning and execution to balance form, function, and budget. Builders must consider local building codes, material costs, insulation requirements, and aesthetic preferences when designing walls and selecting materials. Window placement is also crucial for maximizing natural light and ventilation, which can greatly impact the comfort and functionality of the space.

Various framing methods are available, including traditional stick framing with wood studs or metal framing for increased strength and reduced weight. Metal framing is a viable option for tiny houses if engineered correctly, providing strength and durability. Each method has its pros and cons, and the choice depends on the builder’s skills, budget, and design goals.

When assembling walls, running sheathing vertically can minimize seams and potentially provide stronger shear strength. Finishing one side of the wall with drywall or paneling can impact both insulation and aesthetics. Interior finishes like drywall or paneling are typically hung on the wall framing to complete the look and add durability.

During construction, it’s important to install doors and windows securely to ensure proper insulation and security. For roof framing, the rest of the roof structure must be properly supported by the wall’s top plate to maintain stability.

Interior space planning should focus on optimizing the area around the bed, considering storage solutions, privacy (such as sliding doors), and accessibility. Reflecting on the whole thing, tiny house construction can be more complex than it first appears, requiring attention to detail at every step.

Ultimately, successful tiny house construction hinges on finding the right balance between wall thickness, insulation, structural integrity, and interior space. By understanding the components and factors influencing tiny house wall thickness, builders can create safe, comfortable, and efficient homes that maximize every inch of space.